Products

Punching Perforated Round Hole Titanium Mesh Electrode

Precise Perforations

Superior Corrosion Resistance

Excellent Electrical Conductivity

Consistent and Accurate Hole Patterns

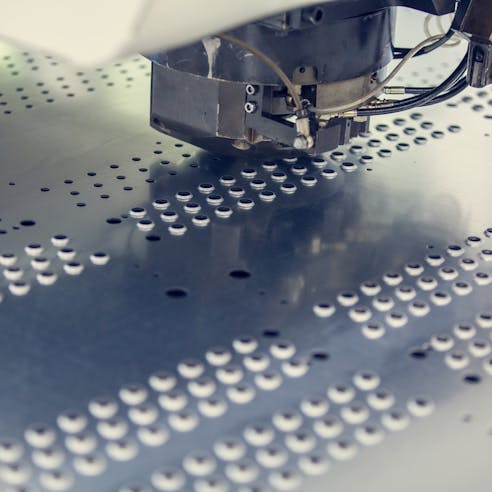

Punching Perforated Round Hole Titanium Mesh Electrode is a cutting-edge and versatile product designed to meet the demanding requirements of electrochemical applications. Crafted with precision using high-quality titanium, this electrode offers exceptional performance, durability, and corrosion resistance.

Featuring a perforated round hole design, this titanium mesh electrode enables efficient mass transfer and uniform current distribution, making it ideal for various electrochemical processes. The strategically placed perforations facilitate the flow of electrolytes, ensuring optimal reaction rates and enhancing overall process efficiency.

The advanced punching technique employed during the manufacturing process ensures precise and consistent hole patterns, resulting in a reliable and uniform electrode surface. This feature is crucial for applications that demand accurate and controlled electrochemical reactions.

Products Specifications

| Material |

Pure titanium |

|||

|

Diameter |

70mm |

|||

|

Thickness |

2mm |

|||

|

Techniques |

Punching |

|||

|

Certificate |

ISO9001:2015 |

|||

|

Color |

Ti-natural |

|||

Products Features

High Efficiency: The perforated round hole design ensures efficient mass transfer and uniform current distribution, leading to accelerated reaction rates and improved process efficiency.

Precise Perforations: The electrode's accurately punched holes provide a uniform surface, allowing for controlled and precise electrochemical reactions.

Enhanced Electrolyte Flow: The strategically placed perforations promote optimal electrolyte flow, facilitating improved reaction kinetics and overall process performance.

Superior Corrosion Resistance: Crafted from premium-grade titanium, the electrode exhibits exceptional corrosion resistance, making it suitable for demanding environments and corrosive media.

Excellent Electrical Conductivity: The titanium mesh electrode offers superior electrical conductivity, minimizing energy losses and maximizing the overall efficiency of electrochemical processes.

Consistent and Accurate Hole Patterns: Advanced punching techniques guarantee precise and consistent hole patterns, ensuring reliability and uniformity across the electrode surface.

Application

Electroplating, providing efficient coating of metal surfaces with protective or decorative layers.

Metal electrowinning, enabling the extraction of metals from solutions with high efficiency and corrosion resistance.

Electrochemical synthesis, facilitating the production of chemicals, pharmaceuticals, and organic compounds.

Water treatment systems, contributing to pollutant removal, disinfection, and wastewater treatment through electrocoagulation and electrooxidation.

Electrocatalysis, serving as a catalyst support for reactions in fuel cells, electrolyzers, and sensors.

Energy storage systems, enhancing the performance and efficiency of supercapacitors and batteries.

Corrosion testing, aiding in the evaluation of materials, coatings, and protective measures in aggressive environments.

Research and development, playing a vital role in laboratory experiments and studies across electrochemistry, chemical engineering, and materials science.

What is punching Technology?

- Material preparation: Selecting appropriate metal sheets, such as steel, aluminum, or stainless steel, to meet the desired hole specifications and application requirements.

- Design and marking: Designing and marking on the metal sheet based on the desired hole size and location to ensure accurate punching operations.

- Tool selection: Choosing suitable punches and dies that match the required hole diameter, shape, and material type.

- Clamping and positioning: Fixing the metal sheet onto the punch press or punching machine, ensuring proper clamping and positioning to avoid errors and misalignment.

- Punching operation: Applying pressure to impact the punch into the metal sheet, forming the desired holes. Punching machines can automatically perform the punching based on preset programs, while punch presses typically require manual control by operators.

- Cleaning and inspection: After punching is completed, cleaning the metal sheet from debris and waste materials, followed by visual inspection to ensure hole quality and accuracy.

Contact us

Tel: 0917-3873009

Phone: +86 18992731201

Email: zhangjixia@bjygti.com

Fax: 0917-3873009

Address: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Whatsapp: +86 18992731201

Hot Tags: punching perforated round hole titanium mesh electrode, China, suppliers, manufacturers, customized, usage, pricelist, for sale, in stock, free sample, porous material, W2 Tungsten Filament, Customized 10 micron porous metal ss316 sintered mesh disc filter, Porous titanium felt, weave reinforcement sintered wire mesh, Ruthenium Iridium Coated Titanium Anode Electrode Plate For Electroplating, GR1 titanium felt paper

-

![Titanium Fiber Felt For LGDL Electrode Materials]() Titanium Fiber Felt For LGDL Electrode Materialsview more>

Titanium Fiber Felt For LGDL Electrode Materialsview more> -

![65um M30 Connection Flat Bottom Porous Metallic Filter Element]() 65um M30 Connection Flat Bottom Porous Metallic Filter El...view more>

65um M30 Connection Flat Bottom Porous Metallic Filter El...view more> -

![30um Porous Metallic Filter Cartridge With DOE]() 30um Porous Metallic Filter Cartridge With DOEview more>

30um Porous Metallic Filter Cartridge With DOEview more> -

![Porous Stainless Steel Flame Arrestors]() Porous Stainless Steel Flame Arrestorsview more>

Porous Stainless Steel Flame Arrestorsview more> -

![Porous Sintered Titanium Filter Cartridge]() Porous Sintered Titanium Filter Cartridgeview more>

Porous Sintered Titanium Filter Cartridgeview more> -

![Sintered Metal Filter Titanium For Filtration]() Sintered Metal Filter Titanium For Filtrationview more>

Sintered Metal Filter Titanium For Filtrationview more>