Products

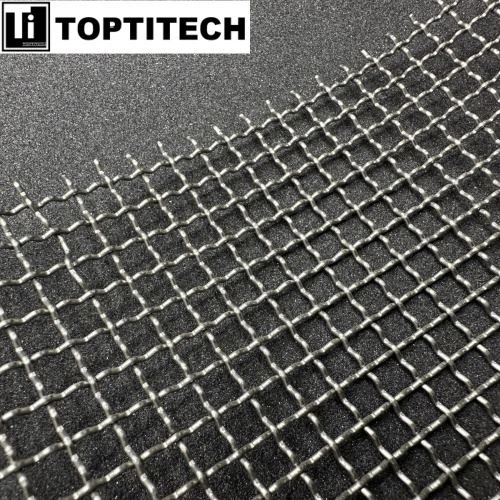

5*5mm Square Hole Titanium Woven Mesh For Beverage Filtering

Optimal Flow Rates

Durability

Corrosion Resistance

Enhance your beverage filtration process with TOPTITECH's 5*5mm Square Hole Titanium Woven Mesh For Beverage Filtering. This meticulously crafted mesh is specifically designed to meet the high demands of beverage filtering, ensuring superior performance and exceptional filtration results.

Made from high-quality titanium, TOPTITECH's woven mesh offers outstanding durability and corrosion resistance, making it the perfect choice for beverage production environments. The square hole design of the mesh allows for precise filtration, effectively capturing even the smallest particles. With a 5*5mm aperture, it strikes the ideal balance between efficient filtration and minimal flow restriction, ensuring a smooth and uninterrupted beverage production process.

Products Specifications

|

Material |

GR1 titanium |

|||

|

Pore size |

5*5mm |

|||

|

Size |

Customized |

|||

|

Thickness |

1mm |

|||

|

Type |

Weave Mesh |

|||

Products Features

Superior Filtration Performance: The square hole design of the mesh ensures precise and efficient filtration. With a 5*5mm aperture, it effectively captures and removes even the smallest particles, such as sediments and solids, ensuring a clean and pure end product.

Optimal Flow Rates: The mesh is engineered to provide optimal flow rates, allowing for smooth and uninterrupted beverage production. It strikes the perfect balance between efficient filtration and minimal flow restriction, ensuring a steady and consistent filtration process.

Durability: Crafted from high-quality titanium, our woven mesh offers exceptional durability. It can withstand the rigorous demands of beverage processing, maintaining its structural integrity over time. This durability translates into a longer lifespan and reduced maintenance costs for your filtration system.

Corrosion Resistance: Titanium is renowned for its excellent corrosion resistance properties. Our woven mesh is highly resistant to corrosion, even in corrosive beverage environments. This ensures that the mesh remains intact and performs optimally, maintaining consistent filtration results.

Enhanced Product Quality: By effectively removing impurities and contaminants, our titanium woven mesh enhances the overall quality of beverages. It helps produce beverages that are free from unwanted particles, ensuring a clean, clear, and refreshing end product that meets high-quality standards.

The production process of titanium woven mesh

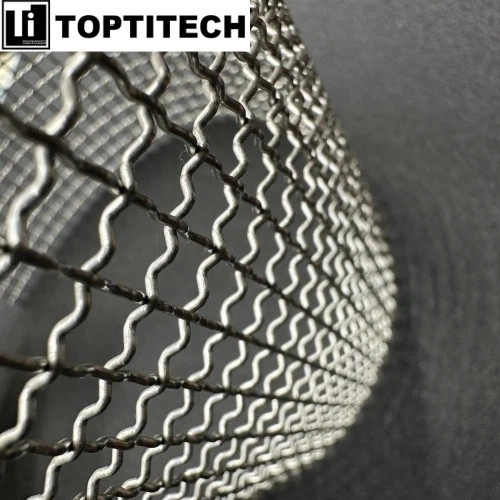

The production process of titanium woven mesh involves precise steps to create a durable and corrosion-resistant mesh structure. Here is a detailed description of the manufacturing process:

Material Preparation

High-purity titanium wire is selected as the raw material for titanium woven mesh production. The titanium wire is carefully cut into appropriate lengths based on the desired mesh size and density.

Weaving Process

The prepared titanium wire is placed on a weaving machine for the weaving process. The weaving machine interlaces the titanium wires together according to the predetermined weaving pattern and requirements, forming a mesh structure. Tension and weaving speed are carefully controlled to ensure the accuracy of mesh size and grid structure.

Cleaning and Deburring

After the weaving process, the titanium woven mesh undergoes cleaning and deburring treatment. This step aims to remove any dirt, grease, and other impurities from the surface, ensuring the purity and quality of the titanium woven mesh.

Heat Treatment

Following the cleaning process, the titanium woven mesh undergoes heat treatment. This step enhances the strength and toughness of the titanium wire, making it more durable. By controlling the temperature and duration of the heat treatment, the mechanical properties and structural stability of the titanium woven mesh can be adjusted.

Surface Treatment

Depending on specific requirements, the titanium woven mesh may undergo surface treatment. Common methods include anodizing, electroplating, and coatings. These treatments improve the corrosion resistance, aesthetics, and adhesion of the titanium woven mesh.

Quality Inspection

Finally, the titanium woven mesh undergoes rigorous quality inspection. Optical microscopes, scanning electron microscopes, and other inspection tools are used to examine the mesh size, grid structure, and surface quality, ensuring compliance with design specifications and quality standards.

Application

TOPTITECH's 5*5mm Square Hole Titanium Woven Mesh is designed specifically for beverage filtering applications but can also be utilized in various other industries. Its versatility makes it a valuable asset for filtration processes in food processing, pharmaceuticals, chemicals, and more.

Contact us

Tel: 0917-3873009

Phone: +86 18992731201

Email: zhangjixia@bjygti.com

Fax: 0917-3873009

Address: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Whatsapp: +86 18992731201

Hot Tags: 5*5mm square hole titanium woven mesh for beverage filtering, China, suppliers, manufacturers, customized, usage, pricelist, for sale, in stock, free sample, porous material, sintered porous powder metal bronze brass mesh sleeve filter elements, Customized Special shaped Stainless Steel Products for Filtration in Food and Beverages, Titanium Porous Mesh, gr5 titanium bolt what is gr5 titanium titanium bolts near me titanium gr5 bolt alloy Titanium screw, sintered titanium aerator plate, specialized alloy 34 9mm titanium bolt

-

![Dia 2x400mm GR1 Titanium Straight Wire For Industry]() Dia 2x400mm GR1 Titanium Straight Wire For Industryview more>

Dia 2x400mm GR1 Titanium Straight Wire For Industryview more> -

![Titanium Pipe For Exhaust And Downpipe]() Titanium Pipe For Exhaust And Downpipeview more>

Titanium Pipe For Exhaust And Downpipeview more> -

![High Quality GR1 Pure Titanium Alloy Ingots]() High Quality GR1 Pure Titanium Alloy Ingotsview more>

High Quality GR1 Pure Titanium Alloy Ingotsview more> -

![Titanium Wire 0.5 Meter To 10 Meters Gr1]() Titanium Wire 0.5 Meter To 10 Meters Gr1view more>

Titanium Wire 0.5 Meter To 10 Meters Gr1view more> -

![GR1 Titanium Coil]() GR1 Titanium Coilview more>

GR1 Titanium Coilview more> -

![100 Mesh GR2 Titanium Mesh Electrode Plate]() 100 Mesh GR2 Titanium Mesh Electrode Plateview more>

100 Mesh GR2 Titanium Mesh Electrode Plateview more>