Titanium alloys, composed of titanium as the base metal along with other elements, offer numerous advantages such as low density, high strength-to-weight ratio, excellent corrosion resistance, and favorable processing properties. These attributes make titanium alloys an ideal choice for aerospace structural materials. In real-world production environments, various types of corrosion can occur in titanium alloys, each with its distinct forms and underlying mechanisms. This article provides a comprehensive overview of the corrosion forms and mechanisms associated with titanium alloys, highlighting their significance and implications.

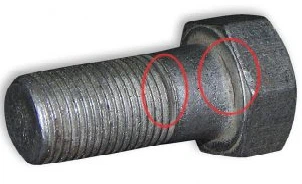

Crevice Corrosion

Crevice corrosion occurs at the crevices or defects of metal components when an electrolyte forms a stagnant microenvironment, resulting in localized corrosion. In neutral and acidic solutions, the probability of contact corrosion in titanium alloy crevices is significantly higher than in alkaline solutions. However, contact corrosion does not affect the entire crevice surface but eventually leads to localized perforation failure.

Pitting Corrosion

Titanium exhibits excellent resistance to pitting corrosion in most salt solutions. However, pitting corrosion is more prone to occur in non-aqueous solutions and boiling concentrated chloride solutions. In such environments, halide ions attack the passive film on the titanium surface, leading to localized pitting with pit diameters smaller than their depths. Certain organic media can also induce pitting corrosion on titanium alloys in halide solutions. Pitting corrosion in titanium alloys typically occurs in high-concentration and high-temperature conditions. Additionally, specific conditions and limitations are necessary for pitting in sulfide and chloride environments.

Hydrogen Embrittlement

Hydrogen embrittlement (HE), also known as hydrogen-induced cracking or hydrogen damage, is one of the early-stage failure mechanisms in titanium alloys. The passive oxide film on the surface of titanium and its alloys possesses high strength, and the susceptibility to hydrogen embrittlement increases with increasing strength. Thus, the hydrogen embrittlement of the passive film on titanium alloys is highly sensitive.

Galvanic Corrosion

The passive oxide film on the surface of titanium promotes a positive shift in titanium's electrode potential, enhancing its acid and water resistance. However, the relatively high potential of titanium alloys can create an electrochemical circuit with other metals in contact, leading to galvanic corrosion. Titanium alloys are prone to galvanic corrosion in two types of media: the first type includes tap water, salt solutions, seawater, atmosphere, nitric acid, acetic acid, etc., where the stable electrode potential of Cd, Zn, and Al is more negative than that of Ti, resulting in a significant increase (6-60 times) in the rate of anodic corrosion. The second type includes H2SO4, HCl, etc., where Ti can be in a passivated or activated state. However, the commonly observed galvanic corrosion during contact usually occurs in the first type of corrosive media. Anodizing treatments are commonly employed to form modified layers on the substrate surface, inhibiting galvanic corrosion.

Understanding the various forms of corrosion and their mechanisms in titanium alloys is crucial for designing corrosion-resistant materials and structures. Crevice corrosion, pitting corrosion, hydrogen embrittlement, and galvanic corrosion are prominent corrosion forms that can affect the performance and integrity of titanium alloys in different environments.