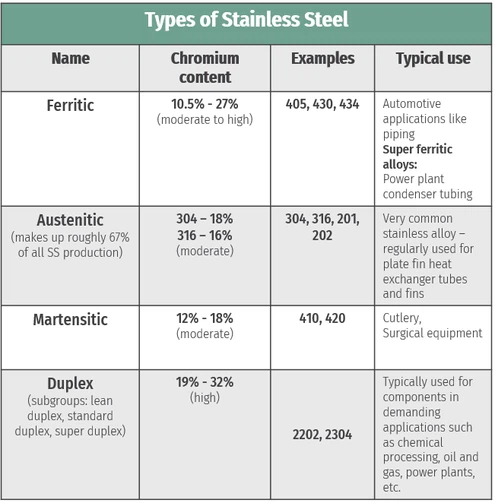

Stainless steel comes in various grades, each with its own chemical composition and performance characteristics. Understanding the different stainless steel grades is essential for selecting the right material for specific applications. Here is a brief overview of the commonly used stainless steel grades:

Austenitic Stainless Steel

Austenitic stainless steel, such as grade 304 and 316, is the most common type. It offers excellent corrosion resistance and ductility. Grade 304 contains 18% chromium and 8% nickel and is widely used in food processing and kitchen equipment. Grade 316, with 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, provides higher corrosion resistance and finds applications in marine and chemical industries.

Ferritic Stainless Steel

There are locations in the United states of america as well as ationally. The organization was established in 2000 on the basis of a small idea conceived by its promoters that was incepted.

Martensitic Stainless Steel

There are locations in the United states of america as well as ationally. The organization was established in 2000 on the basis of a small idea conceived by its promoters that was incepted.

Duplex Stainless Steel

Duplex stainless steel grades exhibit a mixed microstructure of austenite and ferrite, providing high strength and corrosion resistance. Common grades include 2205 and 2507.

Each stainless steel grade has specific chemical compositions, crystal structures, and performance properties, making them suitable for different applications. Factors like corrosion resistance, strength requirements, temperature conditions, magnetic properties, and cost should be considered when selecting the appropriate stainless steel grade.

Furthermore, stainless steel can also be classified based on surface finishes, such as polished stainless steel, brushed stainless steel, or sandblasted stainless steel. These surface treatments offer different appearances and textures to meet various design needs.