5um SS316L Special-shaped Porous Filter Disc For Precision Equipment

Superior Material Properties

Custom Geometrical Design

Enhanced Mechanical Durability

Operational Efficiency

Engineered for critical filtration applications, TOPTITECH's custom-shaped sintered 316L stainless steel filter disc features a trapezoidal geometry with precision-edge polishing, ensuring seamless integration into high-performance systems. The powder metallurgy manufacturing process achieves a controlled 5μm&10um pore structure with uniform permeability, optimized for particle retention in pharmaceutical, semiconductor, or aerospace fluid handling. Hydrogen-sintered 316L material delivers exceptional corrosion resistance against acids, alkalis, and sterilization protocols, while the graded porosity design enhances dirt-holding capacity without compromising flow rates.

Each disc, which is specially made in accordance with CAD specifications, is tested for bubble-point integrity and electrochemical passivation. The trapezoidal profile reduces dead zones in compact assemblies, with laser-cut edges meeting surface finish standards. Ideal for CIP/SIP processes, these discs maintain structural stability across -200°C to 600°C thermal cycles, outperforming polymer membranes in longevity. Optional multi-layer sintering is available for gradient filtration needs in catalyst recovery or nanobubble generation systems.

Products Specifications

| Material |

SS316L |

|||

|

Filtration grade/Pore size |

5um, 10um |

|||

|

Size |

Customized by the drawing |

|||

|

Porosity |

30%-40% |

|||

|

Technique |

Sintering |

|||

Products Features

Precision Filtration Performance

The optimized 5μm&10um pore structure ensures consistent particle retention while maintaining high flow efficiency, ideal for critical applications in chemical and semiconductor industries.

Superior Material Properties

Sintered 316L stainless steel delivers unmatched corrosion resistance against aggressive media, including acids, alkalis, and high-temperature sterilization processes.

Custom Geometrical Design

Trapezoidal profile minimizes flow resistance and dead zones in compact systems, with laser-cut edges polished to meet standards for cleanability.

Enhanced Mechanical Durability

Rigorous powder metallurgy processing creates a robust porous matrix capable of withstanding repeated thermal cycling (-200°C to 600°C) without structural degradation.

Operational Efficiency

The graded porosity design maximizes dirt-holding capacity while allowing easy backflushing, significantly reducing maintenance downtime compared to conventional filters.

Application for Precision Equipment

Semiconductor Manufacturing

Integrated into photolithography equipment for ultrapure chemical filtration, preventing nanoparticle contamination during wafer processing. The trapezoidal geometry facilitates laminar flow in confined spaces of deposition chambers.

Fuel Cell Stack Components

Serves as gas diffusion layer in PEM fuel cells, where the sintered porous structure optimizes hydrogen/oxygen distribution while maintaining mechanical stability under compression.

Aerospace Hydraulic Systems

Deployed in servo valve assemblies for particulate control, with thermal cycling resistance ensuring performance stability from -50°C (high-altitude) to 300°C (engine proximity).

Analytical Instrumentation

Used as frits in HPLC systems, providing consistent backpressure regulation through engineered porosity, superior to polymer alternatives in solvent resistance.

Nuclear Coolant Filtration

Employed in primary loop auxiliary systems, where radiation-resistant 316L material prevents crud accumulation without leaching metallic ions.

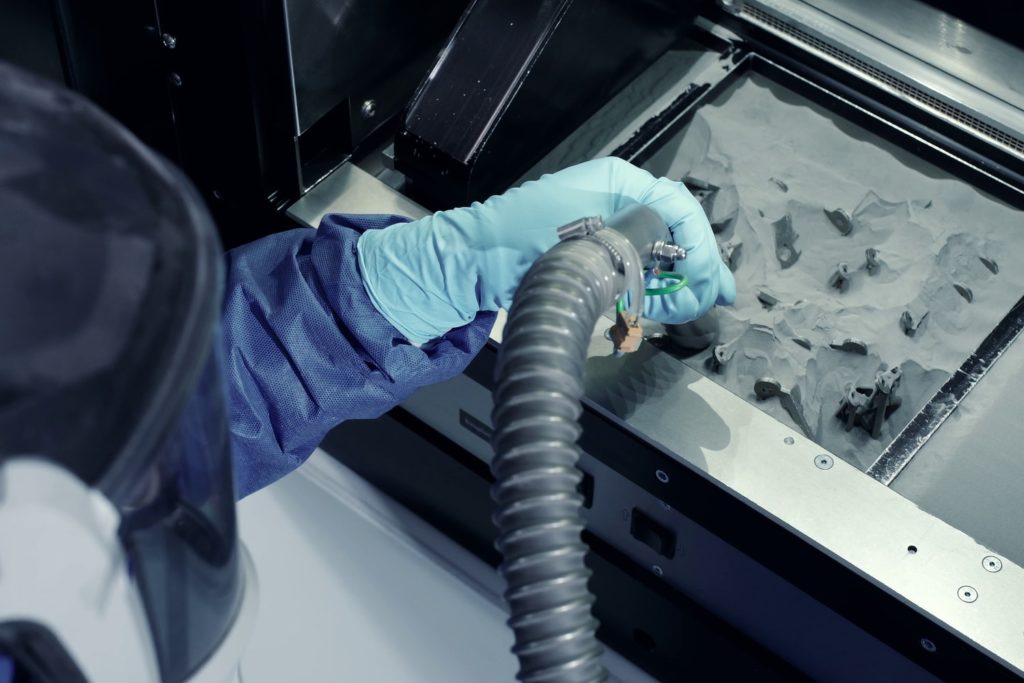

Additive Manufacturing Powder Handling

Captures spatter particles while keeping gas purity levels below 10 parts per million of oxygen in metal 3D printing chambers by filtering inert gas streams.Specification

Contact us

Tel: 0917-3873009

Phone: +86 18992731201

Email: zhangjixia@bjygti.com

Fax: 0917-3873009

Address: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Whatsapp: +86 18992731201

Hot Tags: 5um ss316l special-shaped porous filter disc for precision equipment, China, suppliers, manufacturers, customized, usage, pricelist, for sale, in stock, free sample, porous material, Five layer Sintering Net Filter Element Sintering Net Filter Element Five layer Sintering Net Filter Element by class five layer sintering net filter element amazon Sintering filter, sintered metal mesh tube filter, 304 stainless steel wire mesh, stainless steel cylindrical wire mesh filter, Hight purity Titanium Bar, 316L 5-layer sintered wire mesh filter

-

![1um Porous Metal Filter Tube For Oxygen Distributor]() 1um Porous Metal Filter Tube For Oxygen Distributorview more>

1um Porous Metal Filter Tube For Oxygen Distributorview more> -

![Sintered Filter Cartridge Stainless Steel SUS316L]() Sintered Filter Cartridge Stainless Steel SUS316Lview more>

Sintered Filter Cartridge Stainless Steel SUS316Lview more> -

![Stainless Steel Multi-layer Edging Filter Mesh]() Stainless Steel Multi-layer Edging Filter Meshview more>

Stainless Steel Multi-layer Edging Filter Meshview more> -

![5 layers Stainless Steel Wire Mesh Filter]() 5 layers Stainless Steel Wire Mesh Filterview more>

5 layers Stainless Steel Wire Mesh Filterview more> -

![5 Layers Sintered Metal Wire Mesh Perforated for Industrial]() 5 Layers Sintered Metal Wire Mesh Perforated for Industrialview more>

5 Layers Sintered Metal Wire Mesh Perforated for Industrialview more> -

![SS 316L Wire Screen Sintering Filter Element]() SS 316L Wire Screen Sintering Filter Elementview more>

SS 316L Wire Screen Sintering Filter Elementview more>