Cold cracking, a common phenomenon encountered in welding, can occur in the heat-affected zone of high-carbon steel, medium-carbon steel, low-alloy steel, and medium-alloy steel. In some cases, metals such as ultra-high-strength steel, titanium, and titanium alloys may also experience cold cracking within the weld joint. Understanding the factors contributing to cold cracking and implementing effective prevention and mitigation measures are essential for successful welding operations.

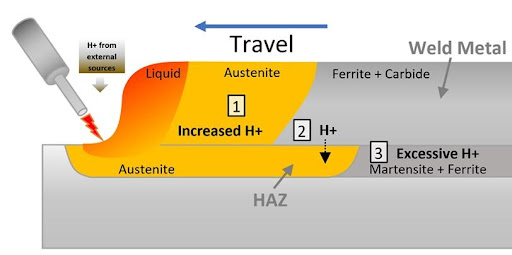

Three primary factors contribute to cold cracking in high-strength steel welding: steel's hardenability, hydrogen content and distribution within the weld joint, and the restrained stress state experienced by the joint. These factors are interrelated and promote the formation of cold cracks. The presence of hydrogen, combined with the formation of martensitic structures during welding, and the tensile stress acting on the joint, contribute to the development of cold cracks. These cracks typically occur either transgranularly or along the grain boundaries and manifest as weld toe cracks, under-bead cracks, or root cracks.

To prevent cold cracking, a comprehensive approach encompassing the chemical composition of the base metal, selection of welding materials, and implementation of appropriate welding procedures is crucial. Consider the following Prevention and Mitigation Strategies:

01

Base Metal Composition

Opt for materials with lower carbon equivalence, as they exhibit reduced hardenability and are less prone to cold cracking.

02

Welding Materials

Select low-hydrogen electrodes and match the strength of the filler metal to the base metal. For materials highly susceptible to cold cracking, consider employing austenitic filler metals.

03

Control Welding Parameters

Proper control of heat input, preheating, and post-weld heat treatment is essential. Adjust the welding parameters to minimize the cooling rate and ensure gradual solidification, reducing the risk of cold cracking.

04

Stress Relief

Employ stress-relief techniques, such as post-weld heat treatment or peening, to alleviate residual stresses and minimize the potential for cold cracking.

Cold cracking poses a significant challenge during welding, particularly in high-strength steel. Understanding the underlying causes and implementing preventive measures are vital for successful welding operations. By considering the base metal composition, selecting appropriate welding materials, controlling welding parameters, and employing stress relief techniques, the occurrence of cold cracking can be significantly reduced. Ensuring a comprehensive approach to welding procedures cultivates high-quality welds, minimizing the risk of cold cracking and enhancing the structural integrity of welded components.