Hot rolling and cold rolling are two key methods employed in steel processing, each exhibiting significant differences in processing temperature, techniques, and resulting product characteristics in industrial applications.

Hot Rolling: Enhancing Plasticity and Efficiency:

Hot rolling is primarily conducted at high temperatures and is commonly used for producing thick plates and structural steel. This method improves the metal's plasticity, reduces deformation resistance, enhances production efficiency, lowers costs, and improves workability. However, hot-rolled products may have relatively rough surfaces, and due to the shrinking during the cooling process, dimensional precision may be compromised. Additionally, hot rolling poses challenges in precisely controlling the mechanical properties of the products and may result in the compression of non-metallic inclusions, leading to layering phenomena that can affect the steel's performance.

![info-1-1 Recrystallization during hot rolling (adapted from Figure 1.8 of [5]). | Download Scientific Diagram](https://www.researchgate.net/publication/323969640/figure/fig1/AS:665766785466368@1535742579861/Recrystallization-during-hot-rolling-adapted-from-8-of-5.png)

Cold Rolling: Precision and Mechanical Performance:

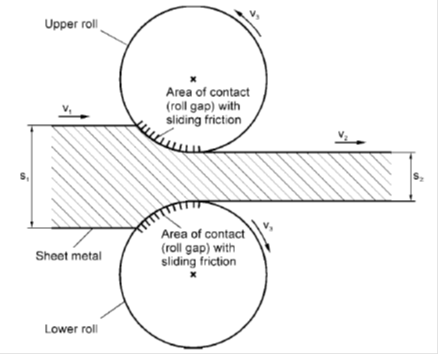

Cold rolling, performed at room temperature, is often employed as a subsequent processing step for hot-rolled products. Cold rolling enhances the material's mechanical properties and dimensional precision, resulting in smoother product surfaces. However, cold rolling can induce work hardening in the material, leading to reduced stamping performance. Furthermore, cold-rolled products typically exhibit higher strength and hardness compared to hot-rolled products, but with lower toughness.

A Comparative Analysis

- Formability and Mechanical Properties:

Hot rolling facilitates the breakdown of the casting structure, refining the steel grain and improving its mechanical properties. On the other hand, cold rolling achieves significant plastic deformation in steel through cold working, thereby increasing the yield point. However, cold-rolled structural steel often exhibits open-section forms, lower torsional stiffness, and inferior torsional resistance.

- Residual Stresses:

Residual stresses in hot-rolled steel primarily result from non-uniform cooling, whereas in cold-rolled steel, they are associated with the cold working process. The distribution of residual stresses differs significantly between the two methods, with hot-rolled steel exhibiting a film-type distribution and cold-rolled steel showing a bending-type distribution.

- Section Buckling:

Cold-rolled steel allows for localized section buckling, harnessing the load-bearing capacity after buckling occurs. In contrast, hot-rolled steel does not permit localized section buckling.

In conclusion, hot rolling and cold rolling are distinct methods with their own characteristics. The choice between these methods depends on specific product requirements and application scenarios. Hot rolling offers improved plasticity, higher productivity, and lower costs but may result in rougher surfaces and challenges in controlling mechanical properties. Cold rolling provides precise dimensions, enhanced mechanical properties, and smoother surfaces but can lead to work hardening and reduced toughness. Understanding the differences and selecting the appropriate method ensures optimal steel processing and meets the desired product specifications in various industrial sectors.