TA2 titanium alloy (Ti-3Al-2.5V) is a lightweight α+β phase alloy renowned for its balanced thermal stability, corrosion resistance, and high specific strength.

Thermal Expansion Behavior

TA2 exhibits a linear coefficient of thermal expansion (CTE) of 8.6×10⁻⁶/°C at 20–100°C, rising to 9.2×10⁻⁶/°C at 500°C. The suppressed CTE increase at elevated temperatures (vs. pure Ti's 9.5×10⁻⁶/°C) stems from Al/Fe solid-solution strengthening, which stabilizes lattice dynamics. Anisotropic CTE variations (Δ0.5×10⁻⁶/°C across rolling/transverse directions) necessitate grain texture optimization during forging to mitigate thermal stress in precision components.

Density and Mechanical Performance

With a density of 4.43 g/cm³ (20°C) and minor thermal derating to 4.38 g/cm³ at 500°C, TA2 achieves a specific strength of 194 MPa·cm³/g, outperforming 42CrMo steel (106 MPa·cm³/g) and rivaling 7075-T6 aluminum. Its tensile strength (860 MPa) and yield strength (550 MPa) remain stable up to 300°C, making it ideal for load-bearing, temperature-critical systems.

Industrial Applications

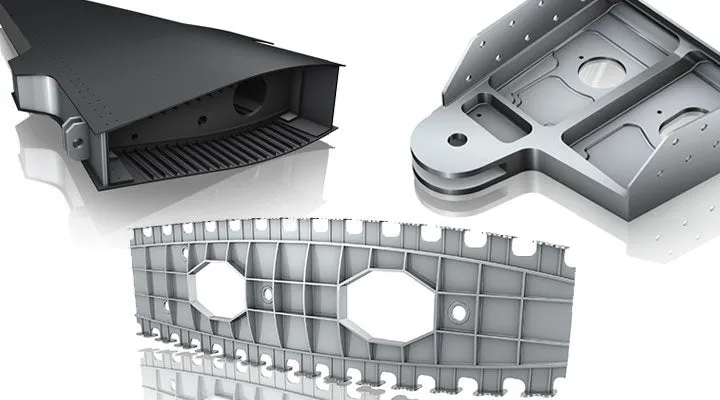

Aerospace Structural Components

TA2 titanium alloy is extensively utilized in aircraft landing gear forgings, where its high specific strength and thermal stability are critical. To address fatigue failure risks, laser peening technology induces compressive residual stresses (-800 MPa) on surfaces, enhancing fatigue life by 200% at 10⁷ cycles. This optimization reduces component weight by 40% compared to steel counterparts while maintaining compliance with AMS 4928 aerospace material standards.

Medical Implant Manufacturing

In orthopedics, TA2 serves as the base material for cementless hip stems fabricated via electron beam melting (EBM). Surface optimization through micro-arc oxidation (MAO) creates 20–30 μm TiO₂ layers with controlled roughness (Ra=3.2 μm), promoting bone cell adhesion. Clinical studies demonstrate 98% implant survivorship over 10 years, meeting ASTM F136 biocompatibility requirements for load-bearing medical devices.

Chemical Processing Systems

TA2-Pd alloy variants (0.2% Pd addition) are deployed as HCl reactor liners in corrosive environments. Hot isostatic pressing (HIP) at 920°C and 100 MPa eliminates 99.7% of internal voids, ensuring structural integrity. This refinement extends operational lifespan from 5 to 15 years in 12% HCl at 80°C, reducing downtime and maintenance costs in chemical plants.

Future Innovation Pathways

- Nanostructured TA2 via Severe Plastic Deformation (SPD)

Equal-channel angular pressing (ECAP) refines grain size to 200–500 nm, boosting tensile strength to 1,100 MPa without ductility loss.

- Additive Manufacturing Advancements

Laser powder bed fusion (LPBF) parameters: 250 W power, 1,000 mm/s scan speed, 50 μm layer thickness. Post-build annealing at 750°C/2h reduces β-phase embrittlement.

- Multifunctional Surface Engineering

CrAlN/TiSiN multilayer coatings (HV=3,500) deposited via HiPIMS enhance wear resistance in turbine blade applications.

TA2 titanium alloy's unique thermomechanical properties and adaptability to advanced manufacturing techniques position it as a cornerstone material for next-generation aerospace, biomedical, and energy systems. Continued R&D in nanostructuring and hybrid processing will further expand its role in high-value engineering solutions.