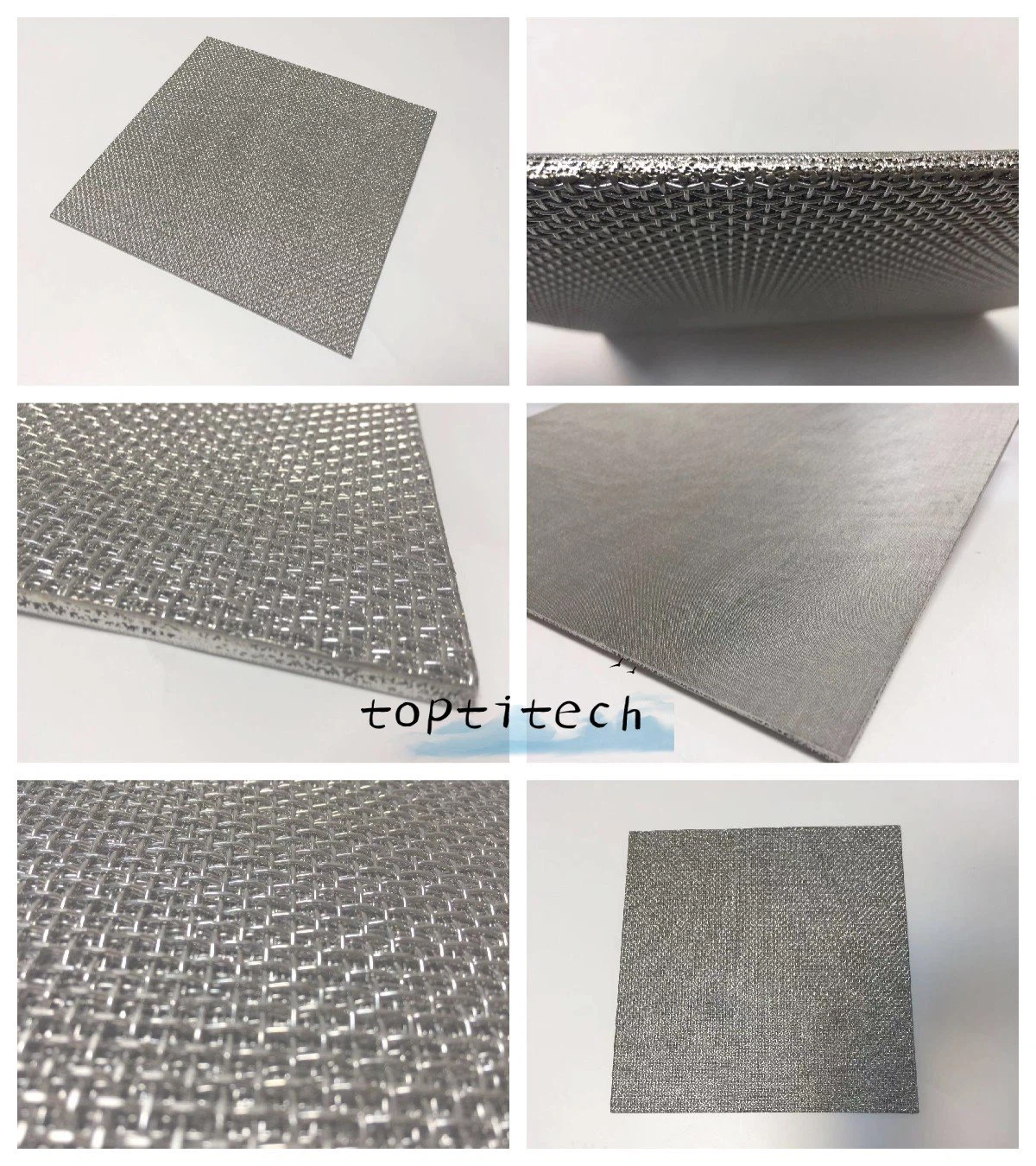

Sintered Metal Stainless Steel Filter Disc

Has an excellent surface-filtering effect;

Has a high filtration accuracy;

High-pressure resistance and mechanical performance.

A sintered metal stainless steel filter disc is a specialized filtration component made through the process of sintering. This technique involves compacting and heating powdered stainless steel particles to create a solid and porous structure.

The sintered metal stainless steel filter disc is designed to efficiently separate solids from liquids or gases by trapping particles within its porous structure. The filter disc offers several advantages, including high strength, corrosion resistance, and durability, due to the use of stainless steel material.

Products Features

1. The use of high-quality materials makes it have good thermal resistance and strong corrosion resistance and is particularly adaptable. It can also be used in the environment.

2. The stainless steel sintering mesh has an excellent surface filtering effect. Because the structure of the surface filtering is selected, its anti-cleaning effect is particularly good, and it can be repeatedly used without affecting performance. It has a long service life.

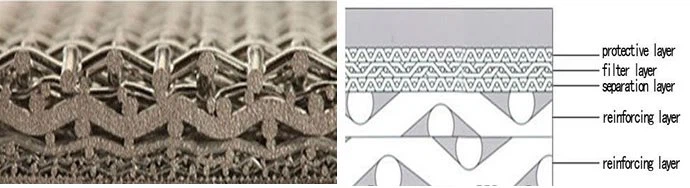

3. And the filter layer of stainless steel is on the second layer, so it can be well protected and diverted and has a high filtration accuracy for the stainless steel sintering net, which can achieve a uniform consistent filtering effect, so it has extremely stable performance.

3. The stainless steel sintering mesh has high-pressure resistance and mechanical performance. Good plastic performance makes it easy to perform processing welding and assembly, easy to use, and easy to operate.

What is a sintered mesh?

Sintered mesh is crafted using a process known as "sintering," which involves the careful assembly of one or more layers of interlaced steel wire mesh. To ensure optimal contact at the wire intersections, the initial step involves uniformly flattening the single-layer woven wire mesh using a roller. Subsequently, the flattened mesh, consisting of one or more layers, is carefully bonded together under mechanical pressure within specialized fixtures.

By utilizing this unique manufacturing technique, the sintered mesh attains exceptional strength and integrity. It possesses a high resistance to mechanical stress and exhibits uniform porosity throughout its structure, making it ideal for various filtration, separation, and support applications.

Contact

tel: 0917-3873009

Phone: +86 18992731201

Email: zhangjixia@bjygti.com

Fax:0917-3873009

Address: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Whatsapp: +86 18992731201

Hot Tags: sintered metal stainless steel filter disc, China, suppliers, manufacturers, customized, usage, pricelist, for sale, in stock, free sample, porous material, weave reinforcement sintered wire mesh, dissolving hydrogen rod halides in water, Industrial sintered mesh filtration tube, Stainless steel sintered filter, stainless steel porous metal filter, Stainless Steel Sintered Wire Mesh Plate

-

![Sintered Filter Cartridge Stainless Steel SUS316L]() Sintered Filter Cartridge Stainless Steel SUS316Lview more>

Sintered Filter Cartridge Stainless Steel SUS316Lview more> -

![Sintered SS316L Powder Filter Cartridges For Hydraulic Filtration]() Sintered SS316L Powder Filter Cartridges For Hydraulic Fi...view more>

Sintered SS316L Powder Filter Cartridges For Hydraulic Fi...view more> -

![Sintered Stainless steel Wire Mesh Filter]() Sintered Stainless steel Wire Mesh Filterview more>

Sintered Stainless steel Wire Mesh Filterview more> -

![Stainless Steel Sintered Mesh For Beer Filtration]() Stainless Steel Sintered Mesh For Beer Filtrationview more>

Stainless Steel Sintered Mesh For Beer Filtrationview more> -

![5 Layers Sintered Metal Wire Mesh Perforated for Industrial]() 5 Layers Sintered Metal Wire Mesh Perforated for Industrialview more>

5 Layers Sintered Metal Wire Mesh Perforated for Industrialview more> -

![Stainless Steel Filter Element]() Stainless Steel Filter Elementview more>

Stainless Steel Filter Elementview more>