In the realm of nylon production, the innovative utilization of titanium pipe fittings has heralded a transformative era. Titanium's exceptional resistance to high temperatures and corrosion has positioned it as the material of choice for crucial stages within the production cycle of nylon, the high-performance fiber dominating the textile industry.

Enhancements in polymerization reactors have been pivotal in advancing nylon production. By integrating titanium pipe fittings within the reactor's internal components-such as pipelines, flanges, and valves-the stability, safety, and lifespan of the reactor have significantly improved.

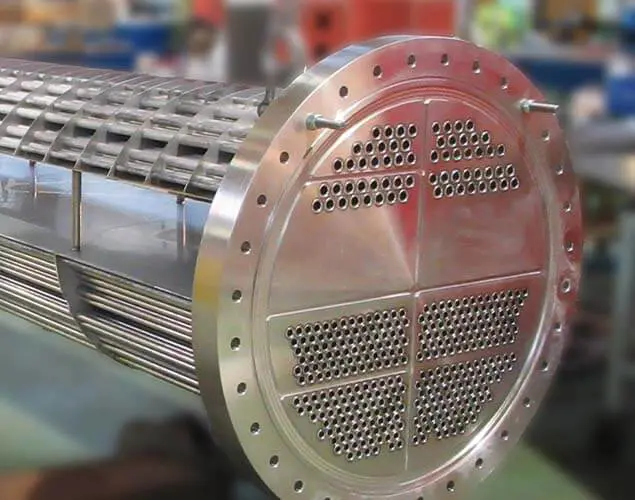

Efficiency and energy conservation in nylon production have been notably influenced by titanium pipe fittings within heat exchangers. Leveraging titanium's superior heat resistance and corrosion resilience, these fittings have not only boosted heat exchange efficiency but also curtailed energy consumption and operational costs.

The secure and reliable transportation of chemically aggressive substances during various stages of nylon production has been facilitated by titanium pipe fittings. With their outstanding corrosion resistance and thermal endurance, these fittings have become the material of choice for chemical substance transport pipelines, ensuring safe and stable conveyance while mitigating risks of leaks and contamination.

Precision and efficiency in spinning components, integral to nylon production, have seen enhancements through the use of titanium pipe fittings. Their smooth, contamination-resistant properties have made them ideal for manufacturing spinning components, thereby elevating yarn quality, uniformity, production efficiency, and overall competitiveness.

Optimizations and enhancements in filtration systems within nylon production, essential for impurity removal, have been realized through the adoption of titanium pipe fittings. These fittings, renowned for their corrosion resistance and non-clogging attributes, have bolstered filtration efficiency, stability, while reducing maintenance costs and operational risks, ensuring purity and quality in nylon production.